Application of Laser Cutting Machine in Single Crystal Germanium Wafer Cutting

(Click 64 )Germanium flakes refer to single crystal germanium materials with a purity of over 99.999%, and are currently one of the most important semiconductor materials in the electronics industry. Due to its excellent characteristics such as high sensitivity, short wavelength, high speed, and low noise, it has been widely used in fields such as wireless communication and infrared detectors. At present, it is commonly used for cutting germanium sheets through wire cutting, knife cutting, laser cutting, etc. Today, we will mainly introduce the application of laser cutting machines in germanium sheet cutting.

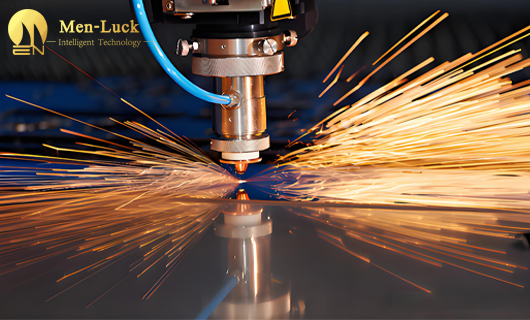

Germanium single crystal wafer is a material with poor thermal properties, therefore it requires high processing technology. Wire cutting and blade cutting are often affected by high temperatures and mechanical stresses, resulting in poor cutting quality. However, choosing the germanium laser cutting machine developed by MenLuck laser production can effectively avoid these drawbacks. The germanium wafer laser cutting machine, also known as the picosecond laser cutting machine, uses ultraviolet cold light as the energy source for non-contact, low thermal effect cutting, thereby avoiding damage to the germanium wafer during the cutting process. It is the preferred germanium wafer cutting equipment.

MenLuck is a manufacturer specializing in the research and development of laser equipment, specializing in fiber laser cutting machines, ultraviolet laser cutting machines, femtosecond laser cutting machines, and more. The existing products have passed CE certification and are exported to multiple countries and regions at home and abroad, providing customers with high-quality laser cutting equipment.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of laser cutting machine in satellite communication field 2025-04-28

Laser cutting machines, with their high precision and non-contact processing characteristics, have become a key process in the manufacturing of satellite communication equipment. From satellite payloads to core components of ground stations, they rely on them to break through th…

Application of laser cutting machine in precision alloy instrument processing 2025-04-24

Precision alloys (such as titanium alloy, nickel-based high-temperature alloy, medical stainless steel, etc.) are widely used in aerospace, medical equipment and precision instruments due to their high strength, corrosion resistance and biocompatibility. Laser cutting technology…

Breakthrough application of laser cutting machine in processing hard and brittle materials 2025-04-24

Hard and brittle materials (such as glass, ceramics, sapphire, single crystal silicon, etc.) are widely used in electronics, optics, semiconductors and other fields due to their high hardness and wear resistance. However, their high brittleness and easy cracking make traditional…

Application of precision laser cutting machines in watchmaking 2025-04-24

In the watchmaking industry that pursues extreme precision and artistic aesthetics, laser cutting machines have become a key process for the manufacture of core components of high-end watches with their non-contact, high-precision and flexible processing characteristics, and hav…