Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts

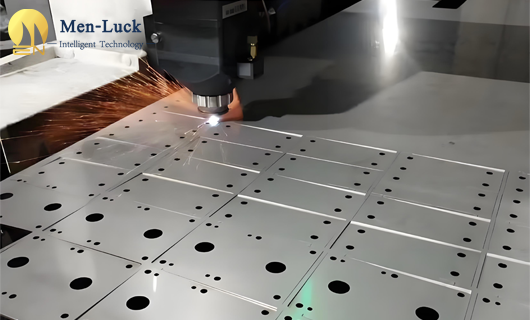

(Click 5 )At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to melt materials and achieves precise cutting.

Compared with traditional cutting technology, the fiber laser cutting machine has an accuracy of up to ±0.05mm, which can accurately process the tiny holes of the seeding device of the planter to ensure the uniformity of seeding; the cutting speed is fast, and when cutting 5mm agricultural machinery steel plate, the efficiency is several times that of the flame cutting machine. At the same time, it can process a variety of materials such as stainless steel and carbon steel, and the heat-affected zone is small, which does not affect the performance of parts.

In practical applications, it is used for tillage machinery parts, which can make the plowshare blade sharp and extend the service life; in the manufacturing of seeding machinery parts, it ensures the precise size of the seeding device and furrow opener; in the processing of harvesting machinery parts, it improves the sharpness of the cutter blade and the adaptability of the threshing drum tooth plate.

As a professional laser equipment manufacturer, MenLuck provides enterprises with suitable laser equipment and complete processing system solutions, as well as professional technical services. Welcome to contact us if you have any needs: E-mail: info@menlaser.com WhatsApp: 86-18796969088

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…