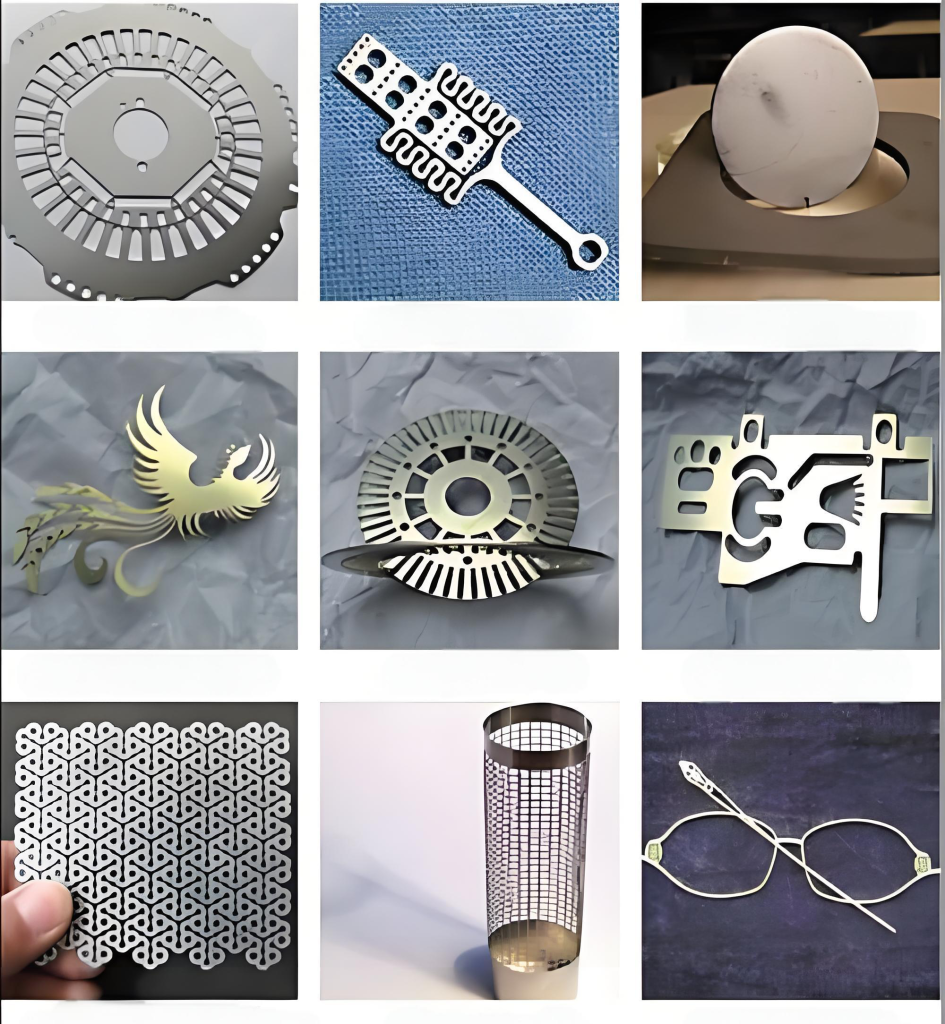

Application materials of precision fiber laser cutting machine

(Click 98 )In recent years, precision fiber laser cutting machines have been widely used in various fields, and their high precision and efficiency have been favored by many industries. From metallic materials to non-metallic materials, from industrial manufacturing to medical fields, precision laser cutting technology is constantly creating remarkable achievements.

In the field of industrial manufacturing, precision laser cutting machines are widely used in industries such as automobiles, aerospace, and electronic equipment. It can accurately cut metal materials, not only achieving cutting of complex shapes, but also maintaining the original properties of the material. Not only has it improved production efficiency, but it has also significantly reduced costs, bringing huge economic benefits to the enterprise.

In addition to metal materials, precision laser cutting technology is also suitable for cutting and processing non-metallic materials. For example, in the cutting process of materials such as textiles, plastics, traditional cutting methods often lead to rough edges or deformation, while precision laser cutting technology can easily solve these problems. Therefore, it is also widely used in industries such as clothing, packaging, and furniture.

Menluck is a professional laser equipment manufacturing enterprise that can perform laser cutting, drilling, engraving, marking and other processing methods. Our main products include precision instrument laser cutting machines, medical equipment laser cutting machines, and hypotube laser cutting machines, providing suitable laser processing equipment for different industries. We welcome enterprises with needs to contact us. E-mail: info@menlaser.com

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …