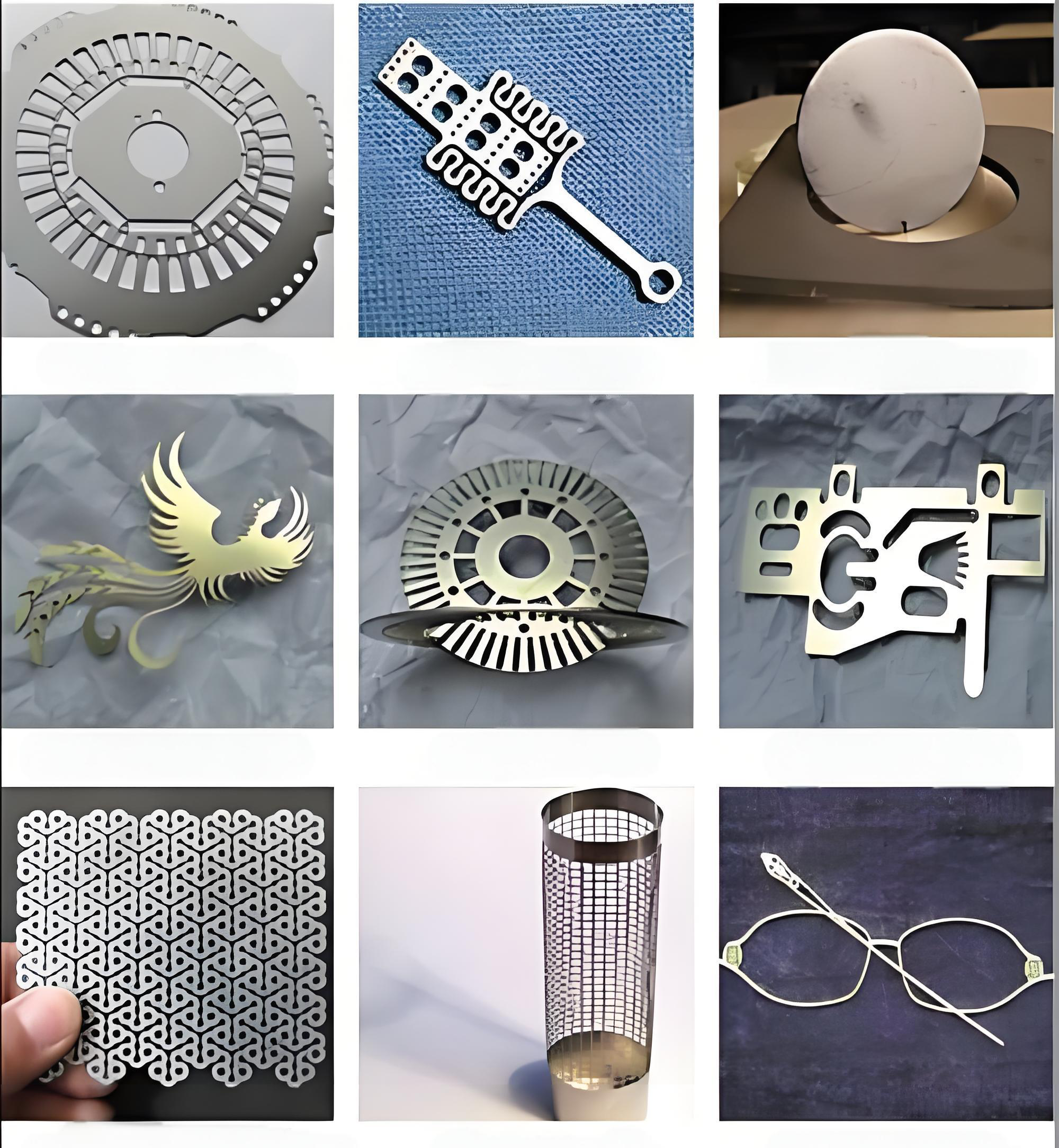

Advantages of laser cutting machines in the hardware industry

(Click 43 )Traditional hardware production and processing technology equipment uses a punch press, and then cooperates with polishing, shearing and bending and other processes to finally form. This method is relatively inefficient for processing companies, and it takes a long time to make molds and costs a lot. In addition, now everyone attaches great importance to energy conservation and environmental protection, which can have a certain impact on the hardware product processing service industry.

The laser cutting machine uses the characteristics of non-contact processing, does not damage the workpiece, and the cut products are not extruded and deformed. The processed products have good service quality, no burrs, no need for manual re-polishing, and save unnecessary processing procedures, optimizing the labor relationship strength of enterprise workers.

The laser cutting machine can choose to directly design and produce various hardware workpiece materials without molds, without mold consumption, and without the need to repair and replace molds. It can save a lot of research on the use of molds, save processing management costs, and reduce social production and operation costs. It is especially suitable for the processing of large and small batches of products.

Laser cutting machines are precise, flexible and efficient, and can effectively process various complex parts of enterprises. You only need to make cutting graphics and import them into the control information system, and then you can set the size data for cutting, which helps workers directly shorten the product processing and manufacturing cycle and effectively improve social labor productivity.

Laser cutting machines cut quickly, the equipment is safe and stable during operation, with low noise and no dust. It will not develop chemical research substances that are harmful to the human body and the environment. It is also a kind of intimate protection for student operators and managers, ensuring the cleanliness of the production site, reducing the need for later investment, reducing pollution, and helping hardware companies to promote the optimization of the education, work and living environment and comply with the trend of environmental protection.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …