Advantages of laser cutting machine in precision electronics industry applications

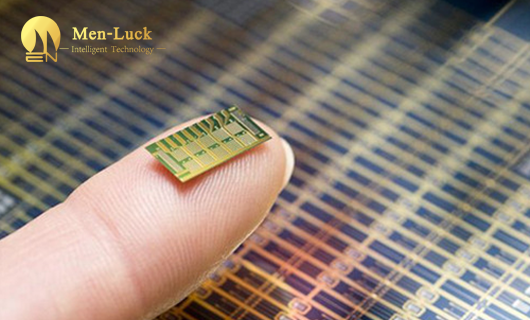

(Click 322 )Laser cutting is a non-contact thermal processing process that uses a high energy laser beam to melt or vaporize a material in a specified area. Compared with the traditional cutting method, the laser cutting machine has a number of advantages, high cutting precision, good cutting quality, can meet the diverse processing needs of different thicknesses, different shapes, different materials, such as in the precision electronics industry used to process chips, circuit boards, photographic head components and other types of precision structural parts.

The biggest difference between laser cutting and traditional processing is non-contact processing, that is, the cutting head has no physical contact with the material, will not cause scratch damage to the surface of the material, will not make the material black and yellow, will not change the performance of the material, and the cutting yield is higher, there are fewer problems in the cutting process, so under normal circumstances, technicians only need to observe the processing process regularly.

Laser cutting machine with advanced numerical control system, according to the drawing requirements can be a variety of complex graphics cutting process, in the case of no equipment component changes, by adjusting the beam output intensity and duration, a variety of cutting cutting, punching or marking operations, widely used in a variety of metal non-metallic materials laser micromachining. And men-luck laser cutting machine can be configured with automatic loading and unloading device, greatly saving labor, improve work efficiency!

The use of precision laser cutting machine can minimize material waste. The focused beam creates a narrower incision, reducing the heat-affected area and reducing the amount of damaged or discarded material; At the same time, it can also use common edge cutting and avoid material scrapping due to deformation when processing flexible materials, which greatly improves the utilization rate of materials; Laser cutting machine can effectively reduce such problems, and can achieve all kinds of processing needs with high precision, high quality and high efficiency.

Men-luck specializes in the production of all kinds of laser processing equipment, mainly laser cutting machine, laser marking machine, laser welding machine, widely used in medical, electronics, semiconductors, integrated circuits and other fields, all equipment through 3C certification, reliable quality, pre-sales and after-sales service is perfect, welcome interested friends to inquire, negotiate business.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…