Video Content

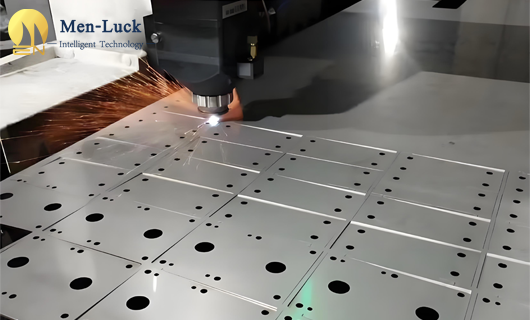

1. Possess the ability of laser cutting, drilling, grooving and other fine processing technology of plane & curved equipment,

2. Machinable materials such as steel & aluminum & magnesium aluminum & copper & molybdenum & nickel & titanium & powder metallurgy & ceramic & sapphire

3. Equipped with self-developed direct-drive mobile double-drive precision motion platform, granite platform & sealed shafting configuration

4. Provide optional functions such as double station & visual positioning & automatic loading and unloading system & processing dynamic monitoring,

5. Equipped with self-developed long & short focal length sharp-nosed & flat-nosed fine laser cutting heads

6. Configure customized copying fixture & slag and dust separation collection module & dust removal pipeline system & safety explosion-proof treatment system,

7. Equipped with self-developed laser micro-machining 2D & 2.5D & 3D CAM software system

WhatsApp:

WhatsApp: Wechat

Wechat

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …

Core application of laser cutting machine in glass photoelectric encoder manufacturing 2025-06-03

As the core component of high-precision angle sensor, the processing quality of the transparent grid of glass photoelectric encoder directly affects the measurement accuracy and signal stability. Laser cutting technology breaks through the bottleneck of traditional processes wit…