A brief analysis of the advantages of glass laser cutting machines

(Click 36 )There are many types of glass, which play an important role in different industries. So what are the ways to cut and punch holes in glass? Commonly used tools for glass cutting and punching are electric punching machines, manual punching machines, laser cutting machines, etc. Each device has different characteristics, and the fastest cutting and punching speed is the glass laser cutting machine, which has significant advantages.

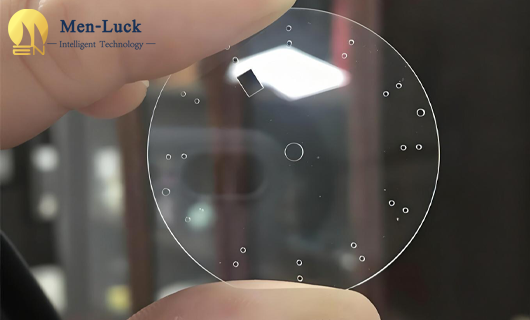

Using a glass laser cutting machine can process ultra-micro holes, with good spot quality and smooth edges, and the aperture size and position of each workpiece are consistent, and the quality of the processed effect is good. This is why laser equipment is widely used.

With the development of laser cutting machines, the accuracy of laser processing is getting higher and higher, the processed hole wall is regular, the density is uniform, the aperture size is consistent, and the quality is very exquisite. Because the processing method of the glass laser cutting machine belongs to cold processing, and the laser focused spot is extremely small, the position of the laser action has very little thermal effect on the surrounding materials, which is not easy to damage brittle materials such as glass.

MenLuck specializes in the research and development, production, marketing and service of laser equipment such as metal laser cutting machines, brittle material laser cutting machines, precision medical equipment laser cutting machines, etc., which are widely used in 3C, medical, hardware, home appliances, etc. Companies interested in laser cutting machines are welcome to contact us. E-mail: info@menlaser.com WhatsApp: 86-18796969088

WhatsApp:

WhatsApp: Wechat

Wechat

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…

Is laser cutting faster than CNC cutting? 2025-06-09

In the manufacturing industry, the efficiency of cutting technology directly affects the production cycle and cost. As mainstream metal processing methods, the speed comparison between laser cutting and CNC cutting (such as plasma cutting) has always been the focus of industry a…

Laser cutting machine: the precision blade that reshapes modern manufacturing 2025-06-07

Laser cutting machine uses photons as a knife, and with its core advantages of non-contact, zero deformation, and multi-material compatibility, it is deeply integrated into the modern manufacturing system. From micron-level medical stents to giant engineering structures, it has …