What are the four stages in the development of cardiac stents?

(Click 1,198 )In recent years, with the increase of the elderly population and the change of our living habits and environment, the incidence rate of coronary heart disease has increased significantly. It is understood that percutaneous coronary intervention (PCI) has become the main method to treat coronary heart disease. With the development of science and technology, biodegradable stents appear in people’s vision. What is biodegradable stents? Today, I will explain the development history of cardiac stents to let you know about biodegradable stents.

So far, the development of cardiac stents can be divided into four stages:

Phase I:

Simple balloon dilatation (PTCA); In 1977, Dr. Gruentzig performed the world’s first coronary artery balloon dilatation, which ushered in a new era of interventional cardiology. He is also known as the “father of interventional heart surgery”.

Phase II:

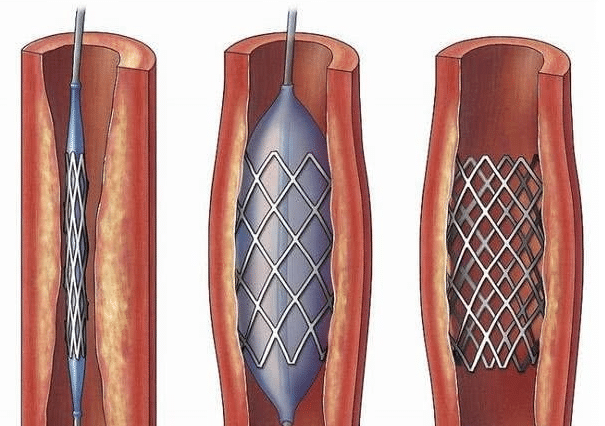

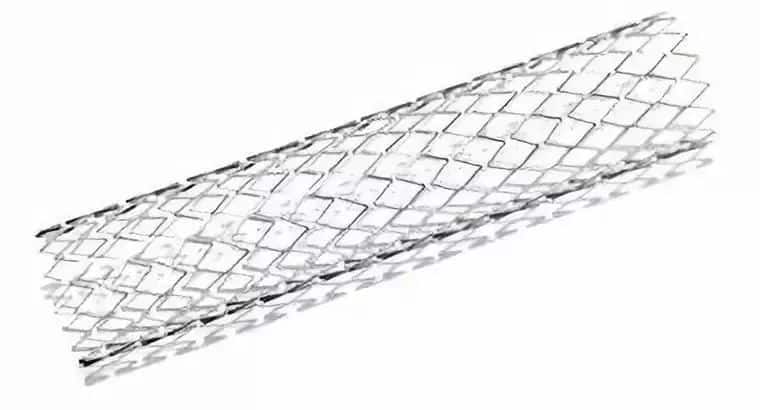

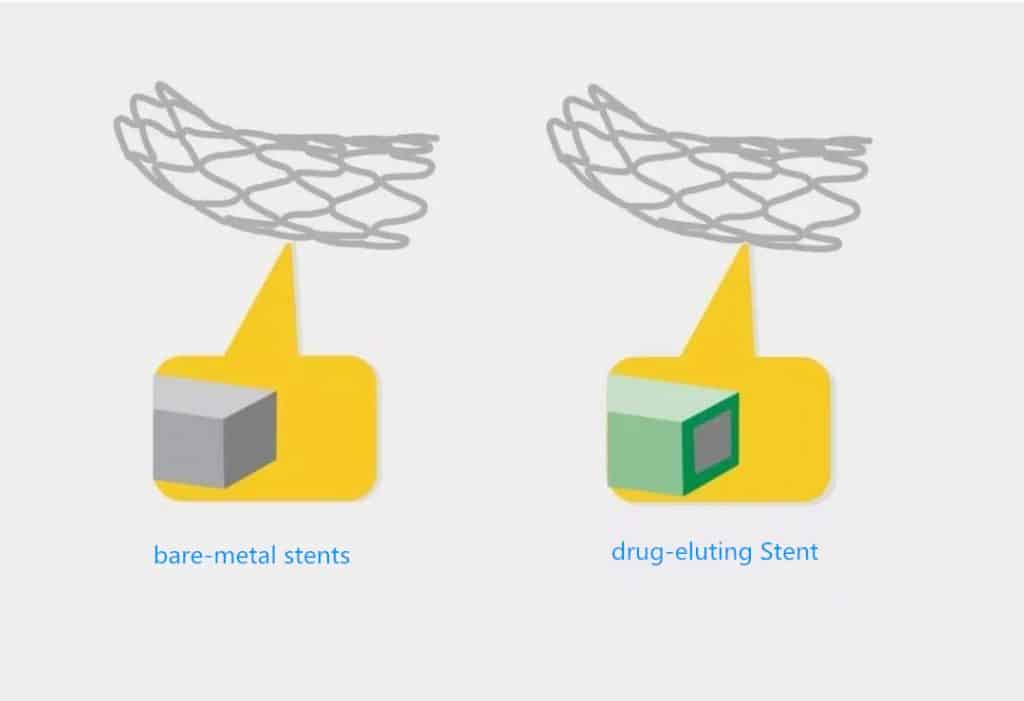

Bare metal support (BMS); BMS is completely made of metal, and it is also the first coronary stent used in clinical practice. Metal materials have good compatibility with blood vessels, which can provide long-term physical support in the diseased areas, thus preventing the stenosis of diseased blood vessels again. However, BMS can only provide physical support and cannot interfere with the inflammatory process of the diseased blood vessels. Therefore, patients are more likely to have secondary lesions of the diseased blood vessels in the late stage (3-5 years later), and once the metal stent is implanted, it will be accompanied by the patient for life, which is also an obvious disadvantage of the metal stent.

Phase III:

Drug eluting stent (DES); The metal surface of DES has an organic polymer coating, which is loaded with drugs that can regulate local inflammatory reaction and cell proliferation. Stents begin to elute drugs from blood vessels within a few days after implantation, and drugs can prevent restenosis more effectively by regulating the process of coronary artery disease. However, the drug preparation can be degraded in the body after the completion of the action, and the metal stent will remain in the body for a long time.

Phase IV:

Biodegradable stent (BVS); Different from the previous cardiac stents, biodegradable stents are completely composed of biodegradable materials (such as polylactic acid). This kind of stent can provide strong support for blood vessels in the short term after treatment, and when the blood vessels are remodeled, they will “retire after success” and directly degrade into water and carbon dioxide in the body. With the unique advantages of degradability, biodegradable stent materials have become the mainstream trend of international cardiac stent technology development.

The biodegradable stent can be completely degraded and absorbed within 3 years. In addition, using traditional metal heart stents, patients need to take anticoagulant drugs to avoid thrombosis. Degradable stents enable patients to get rid of the problem of taking anticoagulant drugs for life, and even because of their degradability, they can implant stents for many times, so that some patients can avoid the risk of chest opening under specific circumstances.

WhatsApp:

WhatsApp: Wechat

Wechat

Femtosecond laser cutting machine reshapes the limit of ultra-precision manufacturing 2025-07-08

In the field of cutting-edge manufacturing that pursues micron or even nanometer precision, traditional processing methods have gradually reached physical limits. The emergence of femtosecond laser cutting machines, with its revolutionary "cold processing" characteristics brough…

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…