The process advantages of laser cutting acrylic

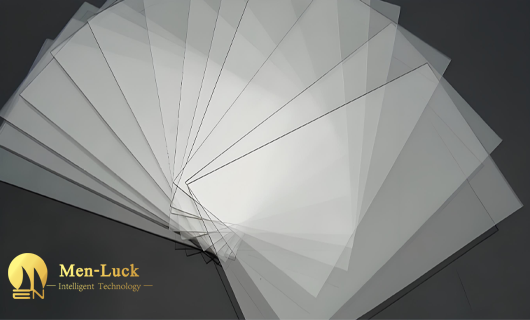

(Click 94 )Acrylic, scientific name is polymethyl methacrylate, also known as organic glass. It has a crystal like transparency, with a transmittance of over 92%, and a density only half that of glass. At the same time, it has the advantages of being non fragile, easy to dye, and easy to process. So it is often cut or carved into various shapes for different purposes such as handicrafts, dust covers, outdoor advertising, etc. The current ideal processing method is to use a carbon dioxide laser cutting machine to cut and process acrylic, which can not only achieve high-precision automated cutting and processing using precision software systems, but also ensure quality and efficiency. Laser cutting is one of the most advanced cutting and processing methods currently available.

Due to the large size of acrylic sheets, specialized equipment is required to cut them into appropriate sizes. Generally, a hook knife can be used for cutting. When reaching a certain level, manually break the acrylic directly. However, this processing method has the disadvantage of large edge breakage, which requires further polishing treatment and has requirements for the thickness of the board. At the same time, it is not possible to accurately cut special shapes such as arcs at once. Saws can also be used for cutting, but the speed should not be too fast to avoid deformation of the acrylic due to overheating caused by friction. In addition, gun knife cutting can also be used, which can accurately cut specific shapes and achieve good cutting effects and high efficiency, but the disadvantage is that there will be certain losses. Laser cutting machines do not have the above-mentioned problems.

Firstly, the cutting seam processed by the laser cutting machine is narrow, and the laser beam is focused into very small light spots, achieving a high power density at the focal point. The material is quickly heated to the point of vaporization, evaporating to form holes. As the beam moves linearly relative to the material, the hole continuously forms a narrow slit. Secondly, laser cutting has good quality and high precision. Non contact cutting minimizes the impact of heat on the cutting edge, resulting in minimal thermal deformation of the workpiece. Completely avoid the collapse of edges formed during material punching and cutting, and will not scratch the surface of acrylic, with smooth and burr free cuts. Finally, save costs. Because laser cutting does not require molds, it saves processing costs and reduces production costs, especially suitable for the processing of large products. And it is possible to cut acrylic products of different shapes into whole acrylic sheets, maximizing utilization.

Men luck provides humanized system solutions and laser cutting equipment for enterprise customers, as well as professional after-sales service and remote after-sales technical support. Welcome to consult and learn from all enterprises.

WhatsApp:

WhatsApp: Wechat

Wechat

Application of laser cutting machines in different fields of precision structural parts 2025-07-02

Electronic information field In the electronic information industry, the size of precision structural parts is getting smaller and smaller, but the precision requirements are getting higher and higher. Laser cutting machines play a key role in the processing of printed circuit …

Working principle and technical advantages of fiber laser cutting machine 2025-06-24

The working principle of fiber laser cutting machine is based on the high energy density characteristics of laser. The high-energy laser beam generated by the laser is focused on the surface of the workpiece through the optical focusing system, instantly heating the material to …

Application of fiber laser cutting machine in the manufacturing of agricultural machinery parts 2025-06-17

At the moment when agricultural mechanization is developing rapidly, fiber laser cutting machine has become a powerful assistant in the manufacturing of agricultural machinery parts with its unique advantages. It takes fiber laser as the core, outputs high-energy laser beam to m…

Precision laser cutting machine: an industrial tool for precision processing 2025-06-13

Precision laser cutting machine is an advanced device that uses high-energy-density laser beams to achieve material cutting. Its core principle is to generate a beam of a specific wavelength through a laser generator, and after focusing through an optical system, a very small sp…