Precautions for laser cutting machine processing PCB boards

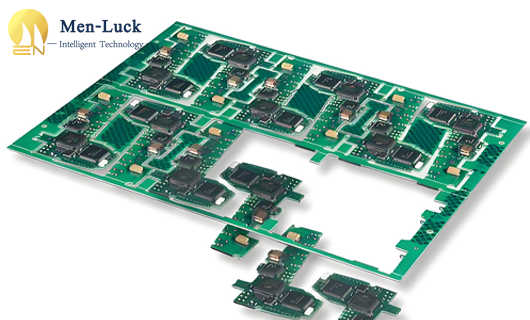

(Click 18 )Laser cutting technology is increasingly widely used in PCB board processing. Its high-precision and non-contact processing characteristics have brought revolutionary changes to the electronics manufacturing industry. In actual operation, it is crucial to master the correct processing method.

Before processing, the laser parameters must be adjusted according to the material characteristics of the PCB board. The cutting of FR-4 materials usually requires a laser power of 30W, and the cutting speed is controlled at about 20mm/s. For high-frequency plates, the power needs to be appropriately reduced to prevent carbonization of the material. The adjustment of the focal length directly affects the cutting quality. It is generally recommended to set the focus 0.1-0.2mm below the surface of the plate.

The selection of auxiliary gas during the processing cannot be ignored. When using compressed air as an auxiliary gas, the pressure should be maintained between 0.3-0.5MPa, which can effectively remove slag and prevent overheating of the plate. Nitrogen protection is suitable for occasions with high requirements for the cutting surface, but the cost is relatively high.

Safety protection measures must be strictly implemented. Operators need to wear special protective glasses, and the working area should be equipped with a fume exhaust system to promptly remove harmful gases generated during the processing. Regularly check the laser’s protective cover and interlocking device to ensure safe operation of the equipment.

The quality inspection link needs to focus on the quality of the cutting edge. The qualified cutting surface should be smooth and flat, without obvious carbonization marks. Use a magnifying glass to check the slit width to ensure that it meets the design requirements, generally controlled within the range of 0.1-0.15mm.

By strictly controlling the processing parameters and optimizing the process flow, laser cutting technology can provide high-quality solutions for PCB board processing. With the continuous advancement of technology, the application prospects of laser cutting in the field of electronic manufacturing will be broader. As a professional laser equipment manufacturer, MenLuck provides customers with high-quality equipment and complete system solutions, and has a professional technical team. Welcome companies with needs to contact us.

WhatsApp:

WhatsApp: Wechat

Wechat

Laser cutting machine processes metal structural parts of smartphones 2025-05-15

In an era where smartphones pursue extreme lightness and high performance, metal structural parts have become the core elements that determine product durability, signal strength and design aesthetics. The limitations of traditional mechanical processing technology in precision,…

Precision innovation of laser cutting machine in heart stent manufacturing 2025-05-12

As the core device of cardiovascular interventional treatment, the structural accuracy and material integrity of heart stents are directly related to the success rate of surgery and the long-term prognosis of patients. Traditional processing methods are difficult to meet the nee…

Innovative application of laser cutting machine processing of coated paper 2025-05-10

Due to its high gloss, printability and crisp texture, coated paper is widely used in high-end packaging, art paper products and cultural and creative products. The traditional die-cutting process has limitations such as high mold cost and poor flexibility. Laser cutting technol…

Application of Thin-walled Tube Laser Cutting Machine in Electronic Cigarette Pipe Manufacturing 2025-05-06

As the core component of electronic cigarettes, the precision processing of electronic cigarette pipes directly affects product performance and user experience. Traditional mechanical cutting methods are prone to deformation of thin-walled tubes, burr residue and other problems,…