Laser cutting machine processes metal structural parts of smartphones

(Click 15 )In an era where smartphones pursue extreme lightness and high performance, metal structural parts have become the core elements that determine product durability, signal strength and design aesthetics. The limitations of traditional mechanical processing technology in precision, efficiency and flexibility have led to the strong rise of laser cutting technology, becoming the “invisible engine” for the manufacture of high-end mobile phone structural parts, and promoting the industry from “mechanical manufacturing” to a new era of “photonic intelligent manufacturing”.

The processing of metal structural parts of smartphones has long faced three major challenges: tool wear in CNC milling leads to tolerance fluctuations, high mold costs for stamping, and environmental pollution risks of chemical etching.

Fiber laser cutting technology has achieved a breakthrough with three core advantages:

Micron-level precision: The processing tolerance of the UV laser cutting machine is ±0.005mm, which meets the precision requirements of 5G antenna slots;

Efficiency leap: The cutting speed of the 3D curved middle frame exceeds 120m/min, which is 8 times higher than that of CNC;

Extreme flexibility: The entire process of importing new model drawings-programming-trial production can be completed in a short time to adapt to the rapid iteration rhythm of the mobile phone industry.

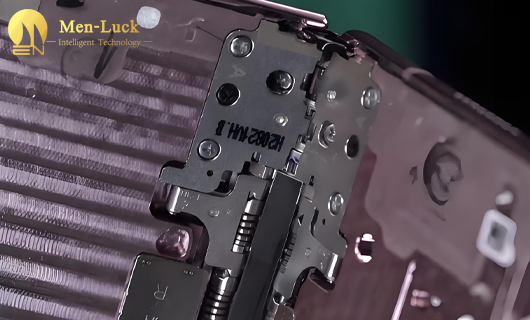

The metal bracket of a mobile phone model with 10x optical zoom module needs to process 120 Φ0.3mm microholes on 0.8mm thick stainless steel. The ultraviolet ultrafast laser cutting machine is equipped with an AI visual positioning system to achieve a coaxial error of <5μm, a 30% reduction in bracket weight, and a yield rate of up to 99.5%.

The hinge of a folding screen mobile phone needs to cut a 0.05mm wide lubricant storage groove on a 0.1mm thick stainless steel sheet. The femtosecond laser cutting machine combined with the nitrogen-assisted process increases the hinge opening and closing life from 200,000 times to 400,000 times.

MenLuck is a professional laser equipment manufacturer that provides integrated intelligent equipment for laser cutting, marking, and welding to customers around the world. Its services cover 3C electronics, medical devices, aerospace, hardware accessories and other manufacturing fields. Companies with demand for laser equipment are welcome to contact us: E-mail: info@menlaser.com

WhatsApp:

WhatsApp: Wechat

Wechat

Precision innovation of laser cutting machine in heart stent manufacturing 2025-05-12

As the core device of cardiovascular interventional treatment, the structural accuracy and material integrity of heart stents are directly related to the success rate of surgery and the long-term prognosis of patients. Traditional processing methods are difficult to meet the nee…

Innovative application of laser cutting machine processing of coated paper 2025-05-10

Due to its high gloss, printability and crisp texture, coated paper is widely used in high-end packaging, art paper products and cultural and creative products. The traditional die-cutting process has limitations such as high mold cost and poor flexibility. Laser cutting technol…

Application of Thin-walled Tube Laser Cutting Machine in Electronic Cigarette Pipe Manufacturing 2025-05-06

As the core component of electronic cigarettes, the precision processing of electronic cigarette pipes directly affects product performance and user experience. Traditional mechanical cutting methods are prone to deformation of thin-walled tubes, burr residue and other problems,…

Application of laser cutting machine in satellite communication field 2025-04-28

Laser cutting machines, with their high precision and non-contact processing characteristics, have become a key process in the manufacturing of satellite communication equipment. From satellite payloads to core components of ground stations, they rely on them to break through th…